※We have a demo unit for testing. Please feel free to contact us.

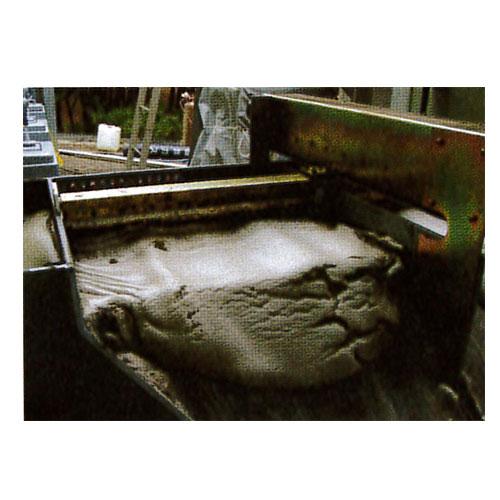

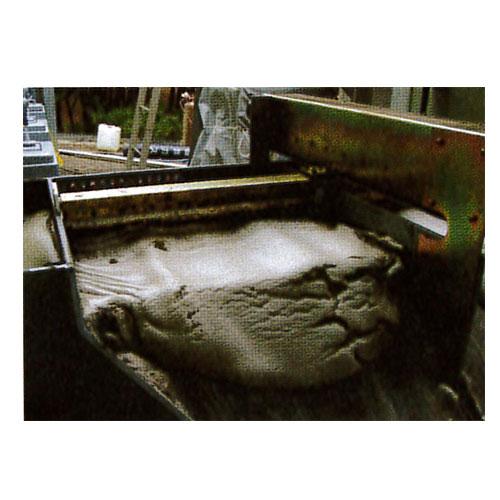

「Electrolysis Sewage Processor」Time-lapse photography

Electrolysis Sewage Processor - Applies to flush paint booth

●Recycle circulation water for flush paint booth

Apply to water miscible oil paint and clear lacquer (UV)!!

No coagulating agent, no medicament !!

●Reuse and purify water before coating

Reduce industrial wastes and save medicament !!

Great effective cost reduction program !!

●Paint sludge is collected automatically. This system is unnecessary to use the chemical administration of a flocculating agent or a booth cleaner. Circulation water will not oxidize easily. Decrease the bad smell in the flush paint booth.

Electrolysis system effects and advantages:

Processing sludge without adhesion. Decrease the spray nozzles being clogged up and sludge will not adhere to booths.

●While electrolyzing, Hydrogen gas and Chlorine gas restrain the growth of bacteria.

●Unnecessary to use the chemical administration of a flocculating agent.

●Various paints are available.

Application:

●Exterior automotive resin parts coating

●Booth for mobiles and metal coating

●Home appliance resin parts

●Booth for water based adhesive

Various applications in processing:

●Application for sewage treatment

Oxidationoxidization and reduction works at the same time, and electrolysis system can use with sewage processing system. It will make these effects as below :

●Reduce varieties of used medicament

●Reduce the amount of sludge

●Reduce running cost and operation cost

●Initial cost is lower than other treatments

●Application for reducing VOC

VOC deodorization system works with water-wash unit and sewage processing system.

It will make these effects as below :

●Managing easily without medicament

●Reduce bad smell and VOC content

●Does not need to drain circulation water

●Reduce the cost of gas and sewage treatment

Verified the reduction of VOC by electrolysis system:

| chemical compound |

before (mg/L) |

after (mg/L) |

reductinon (%) |

|---|---|---|---|

| Benzene | 0.058 | 0.028 | 51.72 |

| Toluene | 710 | 70 | 90.14 |

| Xylene | 64.0 | 2.4 | 96.25 |

Sampling:Electrified for 30 minutes and took samples from sludge.

Assay method:Gas chromatography (data is for reference only)

●Other applications

1. Electrolysed water for degrease and wash (plate metal processing, machining parts)

2. Expand the water-soluble cutting fluid life(refresh and avoid decaying)

3. Deodorization for washing tower(solvent recycle and reduce the bad smell)

4. Clean hazardous substances in sewage(compounds of chloride, heavy metal…etc.)

5. Pretreatment for other sewage system ( reduce the amount of medicament )

Specs

| Model | Amount of treat water ( l / Hr) |

Power source | Power consumption ( W ) |

Expended hours of electrode ( Hr ) |

Dimension ( mm ) |

Weight ( kg ) |

|---|---|---|---|---|---|---|

| ESP-60AD | 360 | 1-phase+Earth 110V 50/60 Hz |

200 (Max. 400W 4A) |

300~500 | 400 x 1400 x 915 | 140 |

| ESP-200AD | 600 | 1-phase+Earth 220V 50/60 Hz |

600 | 300~500 | 650 x 1350 x 980 | 150 |

| ESP-201AD | 800-1600 | 3-phase+Earth 220V 50/60 Hz |

800 | 600 | 1400 x 1300 x 900 | 200 |

| ESP-401AD | 2000-3000 | 3-phase+Earth 220V 50/60 Hz |

1600 | 600 | 2000 x 1500 x 1000 | 40 |

Reference power needs for paint booth – e.g. ESP-201AD

| Ex | Amount of water M3 |

Amount of paint (kg) |

Concentration (kg/L) |

Electrolysis power (kW/hr) |

Electrolysis water (m3/hr) |

Processing time (hr) |

Power needs (kW) |

|---|---|---|---|---|---|---|---|

| 1 | 10 | 50 | 0.005 | 0.5 | 1.5 | 7 | 3.5 |

| 2 | 20 | 100 | 0.005 | 0.5 | 1.5 | 14 | 7.0 |

| 3 | 30 | 150 | 0.005 | 0.5 | 1.5 | 20 | 10.0 |

| 4 | 30 | 200 | 0.0066 | 0.66 | 1.5 | 25 | 16.5 |

| 5 | 50 | 250 | 0.005 | 0.5 | 1.5 | 35 | 17.5 |

| 6 | 50 | 300 | 0.006 | 0.6 | 1.5 | 40 | 24.0 |

※The table as above shows the electrolysis treatment as a reference.

While running, concentration will be lower and the cycle processing treatment will use lower power, too (20~30%).

※Model : ESP-201AD is calculated to treat water 1,500L per hour.