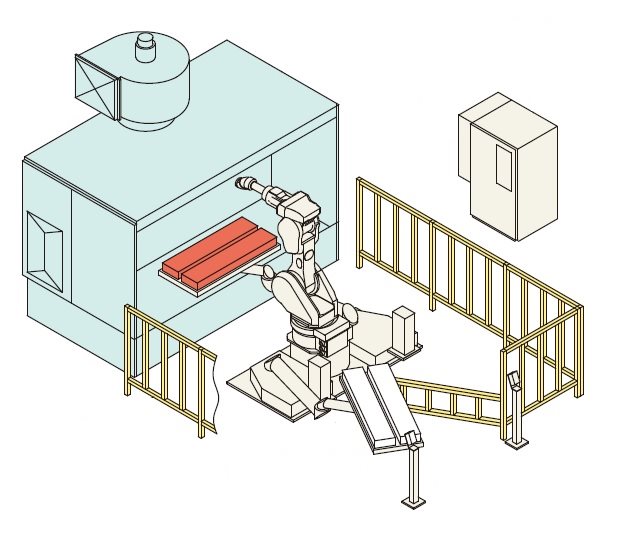

KAWASAKI ROBOT Painting Package Cell

Medium sized work-piece painting cell

The installation space for "Table Painting" was made even smaller.

Servo Wing

1. Space Saving

While suitable for workpieces of a larger size than in the Servo Shuttle, the installation space is made smaller. Because the left and right workpieces are closer together, loading and unloading work is reduced.

2. Even Small-sized Robots Cope with Large Workpieces.

Because there is one painting position, the distance between the workpiece and the robot becomes closer, making the robot possibly smaller than that in Servo Shuttle.

3. Less teaching work

Because the left and right arms can be set for the same painting positions (one position), a single program can be used, thus making the teaching time shorter.

4. Preventing paint mist accumulation

Because the arms are slim with no fixed rails, painting can be conducted above the water, reducing soiling of the booth. In addition, the airflow turbulence inside the paint booth can be minimized.

5. Short Construction Period

This device is delivered pre-assembled. So, it can be installed in as little as one day and you can start production immediately.

| Model | Servo Wing | |

|---|---|---|

| Type | Standard | |

| Table load | 30kg × 2 table | |

| No. of control axes | Robot 6+Servo wing 2 | |

| Control method | Servo control | |

| Teaching playback method | PTP teaching+CP control | |

| Position detection method | Absolute encoder | |

| Arm | Stroke | 2670mm |

| Indexing time | 540°/ sec | |

| Table | Operation angle | Infinite revolution |

| Indexing angle | 90° and arbitrary angle | |

| Indexing time | 1.2 sec / 90° | |

| Uninterrupted rotary speed |

Max 90rpm | |

| Rotary direction | Normal/reverse rotation | |

| Intermediate stop function | The intermediate stop function and multiple coating control function are available. |

|

| Explosion protection | Air pressurized explosion protection and intrinsically safe. Explosion-proof composite type (Expib II BT4 / Exib II BT4) |

|

| Mass | 970kg | |