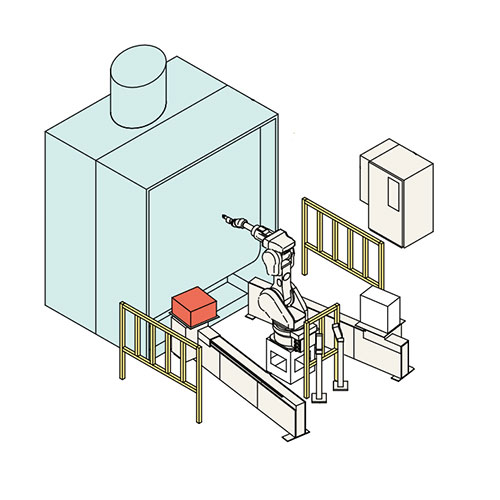

KAWASAKI ROBOT Painting Package Cell

Medium sized work-piece painting cell Ultimate "table painting" type

Servo Shuttle

1. Improvement in productivity

Servo motion provides high speed work transfer and table rotation with shock-less smooth start and stop motion, and also enables continuous rotation tracking with robot and any stand-by position of feeder.

2. Higher coating quality

Controlling the position of the table provides the optimum painting position.

This combined with the high-speed, highprecision robot with the servo shuttle enables high-quality painting.

3. Simple teaching

The simple teaching function provided by the KF series painting robot eliminates time-consuming program teaching.

4. Increased table load

The system can be used for painting large TV cabinets, sanitary ware, automobile instrument panels etc.

5. Simple installation

This complete package is simple to install, but will provide for the painting of the most complex of components.

| Model | Servo Shuttle | ||

|---|---|---|---|

| Type | Standard | Standard | |

| Table load | 20kg × 2 Table | 60kg × 2 Table | |

| No. of control axes | Robot 6+Servo shuttle 2 | ||

| Control method | Servo control | ||

| Teaching playback method | PTP teaching + CP control | ||

| Position detection method | Absolute encoder | ||

| Shuttle | Stroke | 2000、2700、3200、4000mm | |

| Max. speed | 1000mm / sec | ||

| Table | Operation angle | Infinite revolution | |

| Indexing angle | 90° and arbitrary angle | ||

| Indexing time | 0.8 sec / 90° | 1.2 sec / 90° | |

| Uninterrupted rotary speed |

Max 90rpm | Max 45rpm | |

| Rotary direction | Normal/reverse rotation | ||

| Intermediate stop function | The intermediate stop function and multiple coating control function are available. |

||

| Explosion protection | Air pressurized explosion protection and intrinsically safe. Explosion-proof composite type (Expib II BT4 / Exib II BT4) |

||

| Mass | One side: 230 to 310 kg | One side: 350 to 405 kg | |