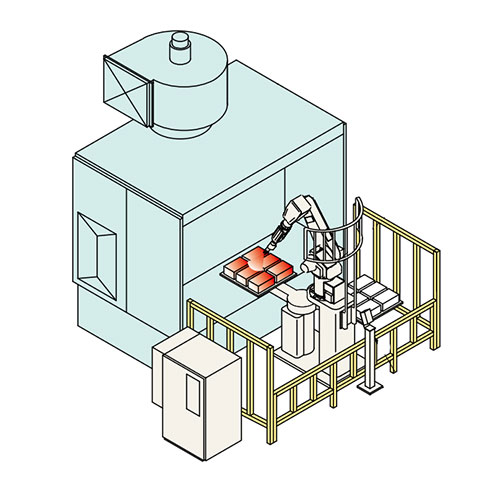

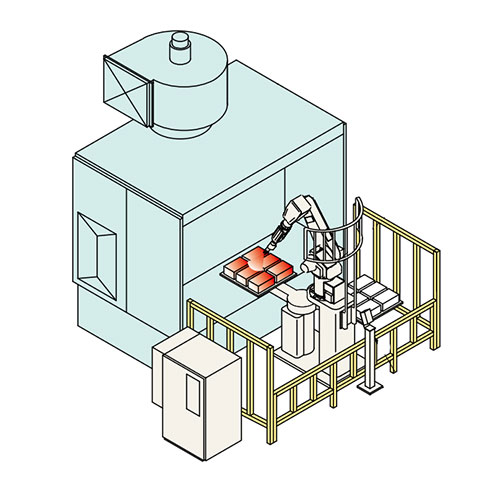

KAWASAKI ROBOT Painting Package Cell

Small sized painting applications A compact but sophisticated system

Servo Twister

1. Small installation space

The minimum installation space required for this system is 2,200 mm wide x 1,966 mm long for a 600 x 600 mm table. Such compactness allows you to install this system in a narrow hand-blowing booth.

2. Rotary table functions

In spite of its small size the Servo Twister provides rotary coating, indexed coating and rotary synchronization functions.

3. 6-axis robots

The Servo Twister installation uses a 6-axis, articulated robot.

4. Shared coating program

The integration of the robot and painting table into one unit allows for programs to be shared by more than one robot.

5. Short installation time

The servo twister cell can be built before delivery, so that the installation time is as shortened and in production as soon as possible.

| Model | Servo Twister | |

|---|---|---|

| Type | Standard | |

| Table load | 20 kg x 2 Table | |

| No. of control axes | Robot 6+Servo twister 2 | |

| Control method | Servo control | |

| Teaching playback method | PTP teaching+CP control | |

| Position detection method | Absolute encoder | |

| Arm | Diameter | 650mm、800mm |

| Operation angle | 135° | |

| Indexing time | 1.8 sec / 135° | |

| Table | Operation angle | Infinite revolution |

| Indexing angle | 90° and arbitrary angle | |

| Indexing time | 0.8 sec / 90° | |

| Uninterrupted rotary speed |

Max 90rpm | |

| Rotary direction | Normal/reverse rotation | |

| Explosion protection | Air pressurized explosion protection and intrinsically safe. Explosion-proof composite type (Expib II BT4 / Exib II BT4) |

|

| Mass | 120kg | |